When were the first arc fault tests carried out?

Scheidt can look back on over 130 years of company history. But how old is the history of arc fault testing? Daniel Sokolic, responsible for design and development at Scheidt, has done some research: "If I had been asked some time ago, I would probably have estimated that the first arc fault tests were carried out in our stations sometime between 1975 and 1980."

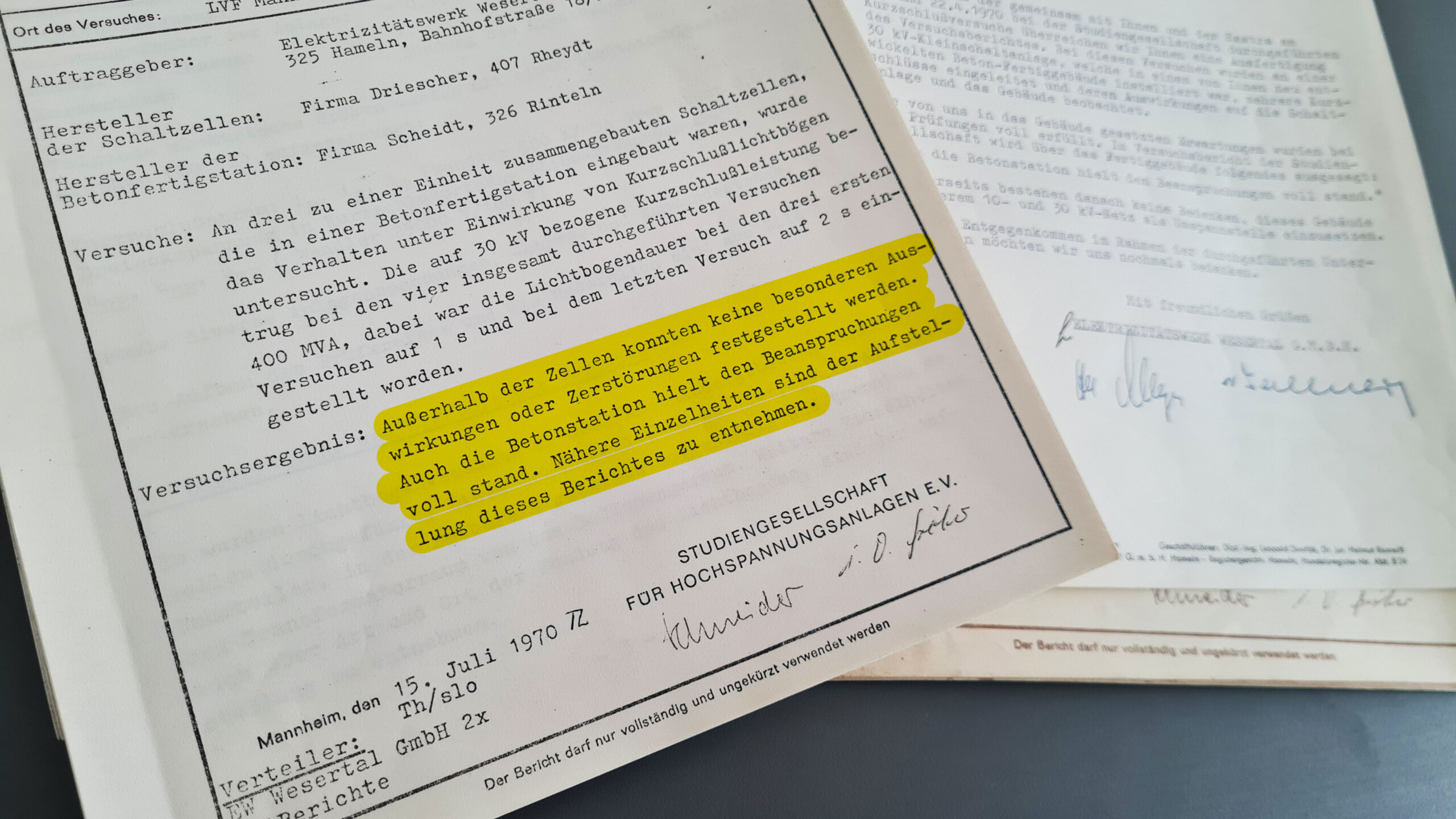

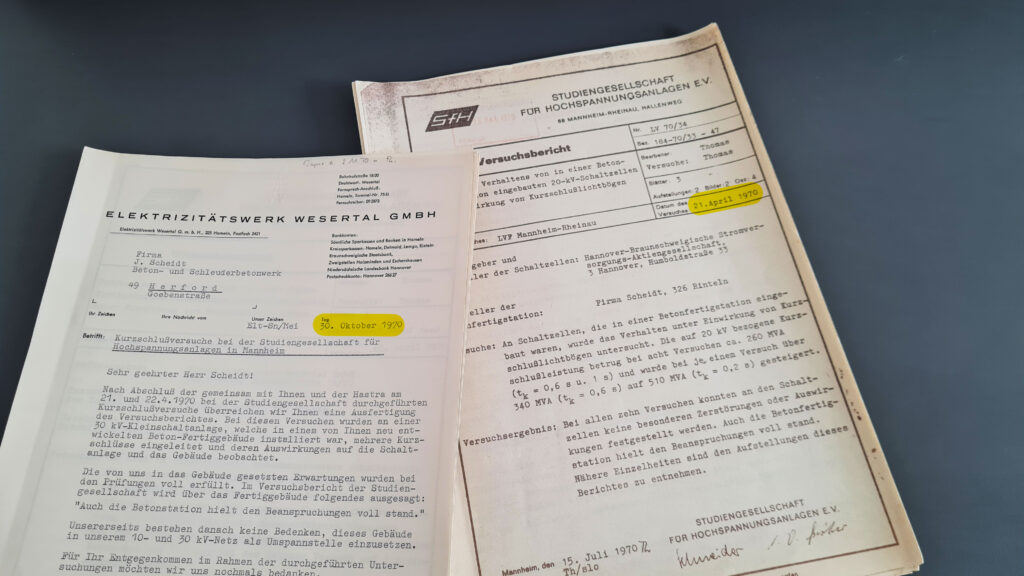

The engineer was very surprised when he noticed two test reports from the "Studiengesellschaft für Hochspannungsanlagen e. V." in the archives of the main plant in Rinteln, which were issued for the Scheidt company in April 1970 - 54 years ago.

Over 54 years of security

In 1970, two accessible stations were tested, each equipped with a 20 kV and a 30 kV system. At that time, the requirements were lower compared to today's standards. The initial short-circuit currents were only 7.6 kA-1s and were increased to 14.7 kA in several tests.

The primary aim was to determine the extent to which the switching cells and stations could withstand an electric arc. Indicators, as we know them today, were not yet used. They were assessed by visual inspection. Nevertheless, some of the earlier approaches have been adopted in today's standardisation. For example, testing with the door closed (pedestrian protection) and with the door open (operator protection).

Development of the arc fault tests

The early tests were basic experiments that paved the way for modern safety standards. Today, arc fault tests involve complex scenarios that require the use of high-tech measuring devices. These advancements have helped to significantly improve safety in high-voltage installations and drastically reduce the risk of accidents.

A legacy of security

Daniel Sokolic, Scheidt's contact for all electrotechnical developments and standardisation regulations, is enthusiastic: "It's impressive not only to come across a piece of company history, but also to see how our predecessors, together with the energy suppliers, laid the foundations for making energy distribution safer well over half a century ago." His conclusion is consistently positive: "It was simply done well by everyone involved at the time!"

Background:

What is an arc fault and how does an arc fault occur?

An arc fault is an undesirable electrical phenomenon that can occur in high-voltage systems. It occurs when an electric current flows through the air between two conductive surfaces without them touching directly. This arc can generate extremely high temperatures and intense light and sound emissions, which is dangerous for both people and technical equipment.

The formation of an arc fault typically occurs in the following steps:

- Voltage overload: In the event of an overvoltage event, such as a short circuit or a switching fault, the electrical voltage at one point can increase to such an extent that it overcomes the insulating capacity of the air or other insulating materials.

- Ionisation of the air: The high voltage leads to ionisation of the air or the insulating material, creating a conductive channel.

- Current flow: A strong electric current flows through this channel, the so-called arc is ignited.

- Plasma and light: The arc generates a hot plasma that can reach temperatures of several thousand degrees Celsius. This leads to intense light and heat radiation.

The dangers of an arc fault not only include potential damage to electrical systems, but also serious injuries to people in the vicinity. Therefore, arc fault testing and corresponding protective measures are an important part of safety in substations.

What does pedestrian protection and operator protection mean?

In arc fault tests, pedestrian protection and operator protection are two essential test procedures designed to ensure that both people in the vicinity and operating personnel are protected from the dangers of an arc fault.

Pedestrian protection

Pedestrian protection refers to the protection of persons who are in the vicinity of electrical installations but do not operate them directly. This involves checking that the equipment remains safe with the doors closed and an arc fault occurring. The test focuses on ensuring that no hot gases or debris can escape to the outside and thus endanger passers-by.

Test steps for pedestrian protection:

- Preparation: The electrical system is completely closed and indicators are set up at critical points in accordance with standard specifications.

- Simulating the arc fault: An artificial arc fault is generated within the switchgear.

- Assessment: The results are analysed by the test engineer to assess whether the criteria according to EN 62271-202 for pedestrian protection are met.

Operator protection

Operator protection refers to the protection of personnel who work directly with the electrical equipment. These tests are carried out when the access door to the plant room is open to ensure that the operating personnel are not endangered by a possible arc fault.

Test steps for operator protection:

- Preparation: Access doors to the system are opened to simulate a realistic operating situation. Indicators are set up in front of the switchgear in accordance with the standard specifications to simulate the presence of operators.

- Simulating the arc fault: An artificial arc fault is generated in the switchgear.

- Assessment: The results are analysed to assess whether the criteria according to EN 62271-202 for operator protection are met.

These tests are essential to ensure the safety of both passers-by and operators and to ensure that electrical systems comply with current safety standards.