Home page " Products " Switch houses and buildings " SCHEIDT INDIVIDUAL SH " Technical data

SCHEIDT INDIVIDUAL SWITCH HOUSE

SCHEIDT INDIVIDUAL SH in detail

Your boat, your car, your shed. We build the latter for you - because we know exactly how to make it perfect. Tell us what you want it to look like!

Data on Scheidt SH

Key plus points

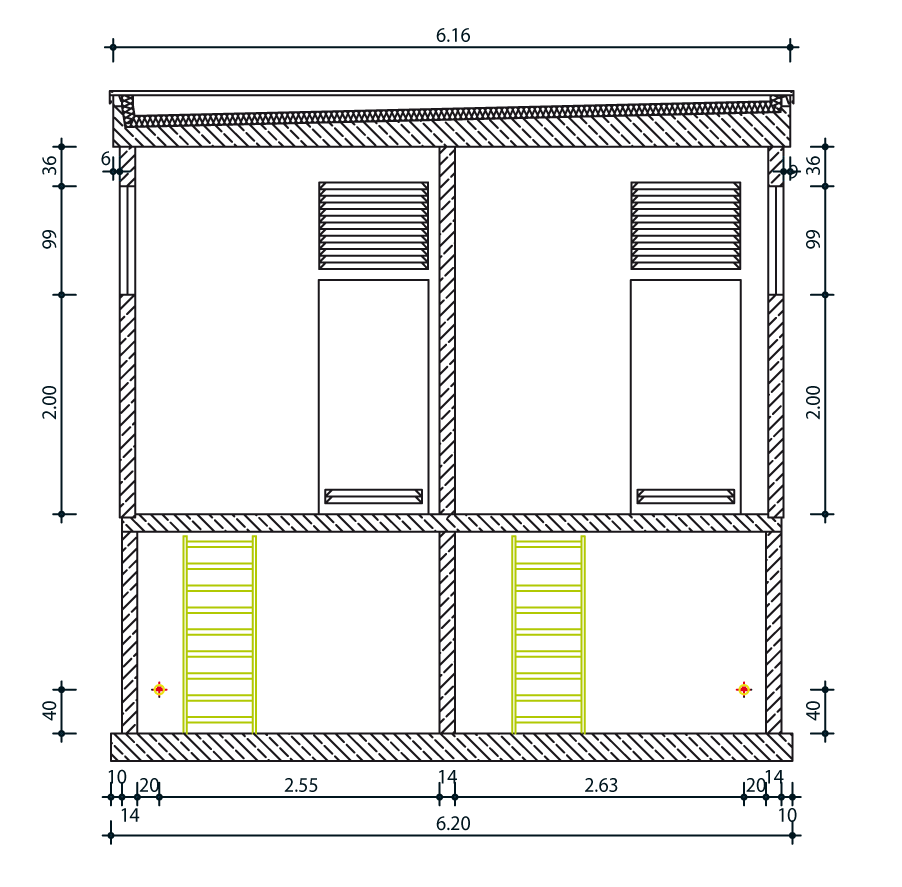

- Prefabricated reinforced concrete building, grade C35/45

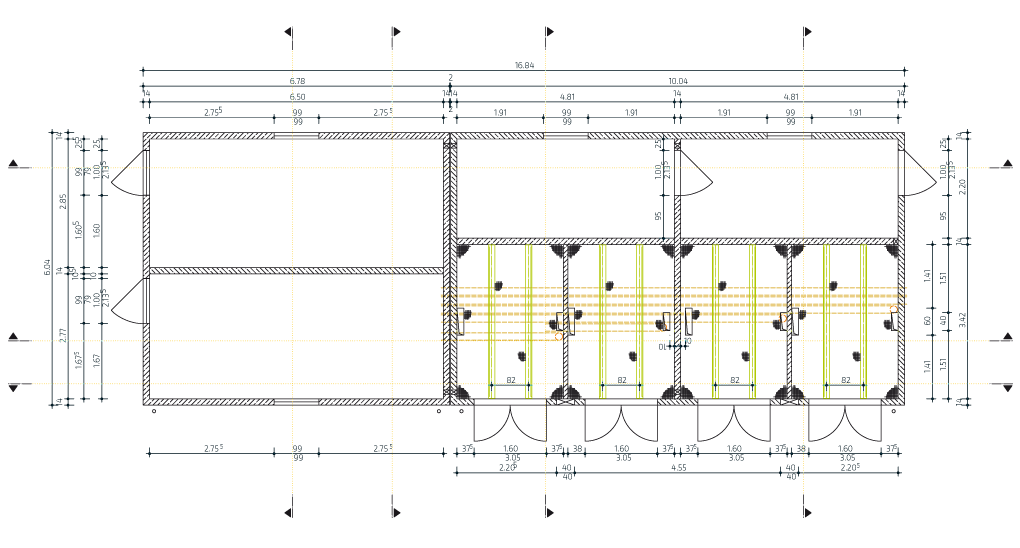

- Produced in element construction, can be manufactured in almost all dimensions

- Single and multi-storey

- With different roof shapes

- Short construction time due to prefabrication/equipping of the individual elements in the factory

Cellar

- Manufactured in the factory

- Monolithic without construction joint

- Maximum water and oil tightness without additional coatings

- Width min. 3 m to max. 5 m

- Length min. 6 m to max. 12 m

- Additional dimensions: Composition using individual components or a waterproof in-situ concrete trough

- Oil collection surface can optionally be provided with an additional oil-resistant coating

- Waterproofing of the tray possible with WHG-approved system

- Sealing systems for cable and/or pipe feed-throughs from various certified manufacturers in use

Walls

- Rigidly connected roof and wall elements

- Prefabricated walls rest on strip foundations, basement walls or concrete intermediate floors

Intermediate floor

- To accommodate the switching and building technology

- Concrete intermediate floor/concrete floor slab constructed from precast concrete elements or poured in-situ concrete (thickness according to structural requirements)

- Optional raised intermediate shelf made of non-slip coated composite wood panels

- Transformers can be mounted on adjustable, galvanised steel transformer rails

Roof

- Standard cassette roof with 2 % roof pitches

- Circumferential concrete attic composed of one or more separately manufactured elements

- Moisture penetration protection

- Individual roof elements are rigidly connected to each other and the walls

- Common variants: e.g. flat and pitched roofs

- Other special roof shapes (e.g. pitched roof/wood constructions) are planned specifically according to customer requirements

Facades

- Station body exterior with highly elastic textured coating

- On customer request, facade design of the building with e.g:

- Friction plaster

Pebble plaster

Clinker brick

Exposed aggregate concrete

Design as half-timbered imitation

Graffiti, ...

Interior fittings

- Interior walls, including the inner roof surface, are coated with a white, wash-resistant binder coating

- Integration option for anchor channels or threaded bushes

- Empty conduits can be set in concrete for the electrical installation

- Rails, sockets and armouring, as well as all metal parts of the station body that are not part of the operating circuit, are electrically connected to each other so that a collective earth connection can be routed out of the station

Doors and ventilation

- Various built-in parts such as doors, ventilation grilles, pressure relief flaps or windows in different sizes and materials can be used on the front and long sides as required

- Ventilation systems in the roof possible, such as roof ventilation bonnets, pressure relief bonnets and fans

- The built-in doors with 3-point locking and panic lock are prepared for on-site profile cylinders

Structure assembly / composition

- Assembly/composition of the structures: on the construction site